- Specifications

- Character

- Related Products

| Max. Work Piece Size L x W x H (mm) | 800 x 600 x 265 |

|---|---|

| Maximum height of cutting workpiece | 270 |

| Max. Work Piece Weight (kg) | 400 |

| X x Y stroke (mm) | 400 x 300 |

| U x V Stroke (mm) | 160 x 160 |

| Z Stroke (mm) | 270 |

| Max. Cutting Taper (mm) | ±32˚ / H100mm |

| Max. Wire Spool Weight (kg) | 16 |

| Foot Print W x D x H (mm) | 2250 x 2600 x 2280 |

| Water System Capacity (L) | 730 |

| Machine Weight (kg) | 3500 |

Controller Specifications

| Controller System | Windows |

|---|---|

| Control Device | 64 - bit Industrial PC |

| Storage Device | ≥ 30GB SSD |

| Screen Display | 21.5" Color TFT Touch Screen |

| Data Input | Keyboard, Mouse, USB, Ethernet, FTP |

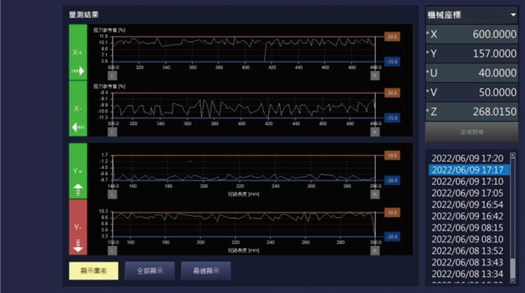

| Servo control method | Full closed loop (Linear scale) |

| No. of Control Axes | 5 Axes/ 6 Axes (Opt.W Axis) |

| Simultaneous Axes | 4 Axes/ 5 Axes (Opt.W Axis) |

| Min. Command Unit | 0.0001mm/ 0.00001 inch |

| Max. Command Range | ±9999.9999mm |

| Command Type | mm/ inch |

| Cutting data Memory | 99999 Sets |

| Power type | MOSFET Non-electrolysis power |

| Ignition Power Supply | 32 Steps,53V~138V |

| On time | 24 Steps |

| Off time | 43 Steps |

| Discharge Mode | Rough Cut/ Skim Cut/ S Power/ MST Power available for AP/AZ series only |

| Controller Functions | |||

|---|---|---|---|

| Backlash compensation | Pitch compensation | Program management | Program edit Program simulation |

| Anti- collision | Cutting path display | Linear/Circular interpolation | Auto corner |

| N code move | Sub program | Multi-blocks skip | Corner control function |

| MDI function | Taper setting | 4 axes cutting | M01 stop |

| Single block | Mirror | program rotation | Axis exchange |

| Short back | Constant feed/ Servo feed | 2nd software limit | Axis Rotation |

| Auto aligment (edge, center) |

Dry run | Single block stop | Reference point setting |

| Reference point return | Retrace to start point/ Start point return |

Auto Power recovery (Option) | Diagnosis |

| Cutting log | Maintenance dashboard | Auto compensation for wire comsumption | Lead-in/ Lead-Out Control |

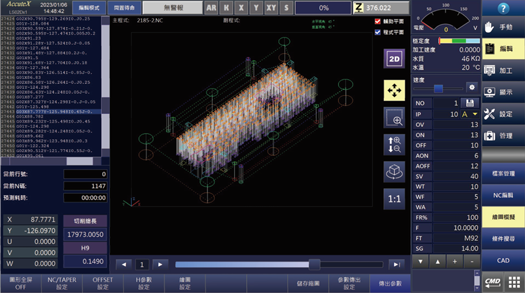

a. New Windows Controller (EtherCAT level control system)

Dual industrial-grade PCs are equipped with high-performance CPUs and adopt Ethernet serial architecture to achieve high-speed and real-time synchronous motion.The convenient EtherCAT universal expandability enables the machine to have more intelligent applications.

Processing history library

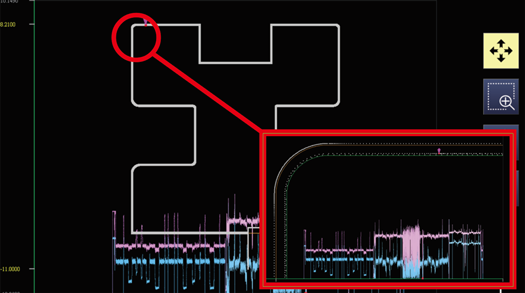

Fast drawing performance

Automatic alignment

Built-in CAD / CAM

Processing history library

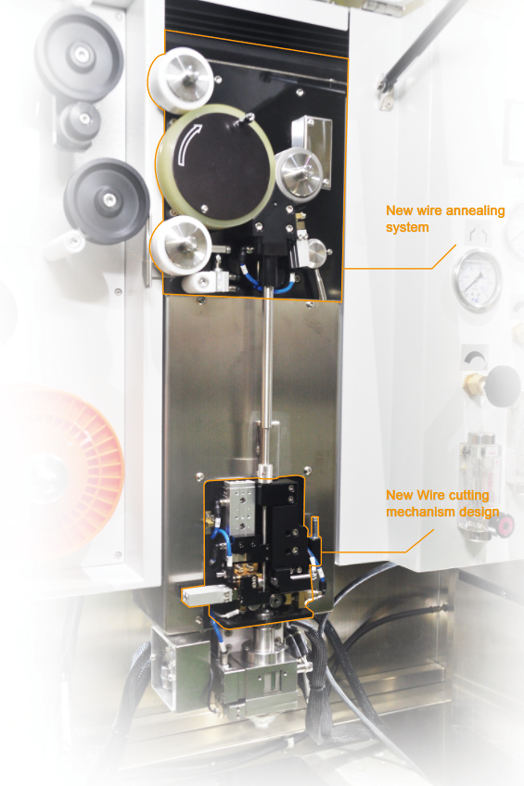

b. New generation of AWT (More reliability and repeatability)

Inherit the features of high reliability and easy maintenance of the AccuteX AWT function, the new generation has improved the straightening and wire cutting mechanism (patent pending), and equipped with a new type of straightening, annealing, and cutting power supply.

This enables the wire to have better straightness and wire end quality, and achieve a higher success rate in threading through high thickness workpieces.

The new mechanism is suitable for wire diameters from 0.1mm to 0.3mm(*).

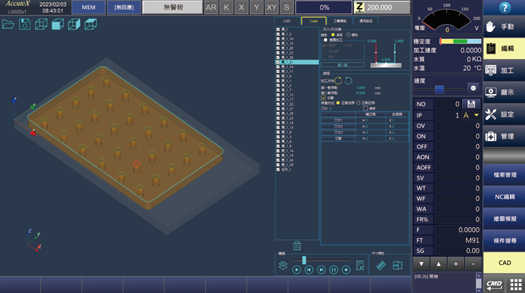

c. Industry 4.0 Intelligent Manufacturing Integration System

AccuteX machine is capable with industry 4.0 who has M2M (machine to machine) protocol to collaborate with Robots and other machines. Flexible Real-time production can be made by Intelligent Manufacturing Integration System to meet full-automation demand.

Download

Download