- Specifications

- Character

- Related Products

| Max. Work Piece Size L x W x H (mm) | 980 x 775 x 295 |

|---|---|

| Maximum height of cutting workpiece | 270 |

| Max. Work Piece Weight (kg) | 550 |

| X x Y stroke (mm) | 600 x 400 |

| U x V Stroke (mm) | 160 x 160 |

| Z Stroke (mm) | 300 |

| Max. Cutting Taper (mm) | ±32˚/ H100 |

| Max. Wire Spool Weight (kg) | 16 |

| Foot Print W x D x H (mm) | 2600 x 2700 x 2335 |

| Water System Capacity (L) | 830 |

| Machine Weight (kg) | 4400 |

Controller Specifications

| Controller System | Windows |

|---|---|

| Control Device | 64 - bit Industrial PC |

| Storage Device | ≥ 30GB SSD |

| Screen Display | 21.5" Color TFT Touch Screen |

| Data Input | Keyboard, Mouse, USB, Ethernet, FTP |

| Servo control method | Full closed loop (Linear scale) |

| No. of Control Axes | 5 Axes/ 6 Axes (Opt.W Axis) |

| Simultaneous Axes | 4 Axes/ 5 Axes (Opt.W Axis) |

| Min. Command Unit | 0.0001mm/ 0.00001 inch |

| Max. Command Range | ±9999.9999mm |

| Command Type | mm/ inch |

| Cutting data Memory | 99999 Sets |

| Power type | MOSFET Non-electrolysis power |

| Ignition Power Supply | 32 Steps,53V~138V |

| On time | 24 Steps |

| Off time | 43 Steps |

| Discharge Mode | Rough Cut/ Skim Cut/ S Power/ MST Power available for AP/AZ series only |

| Controller Functions | |||

|---|---|---|---|

| Backlash compensation | Pitch compensation | Program management | Program edit Program simulation |

| Anti- collision | Cutting path display | Linear/ Circular interpolation | Auto corner |

| N code move | Sub program | Multi-blocks skip | Corner control function |

| MDI function | Taper setting | 4 axes cutting | M01 stop |

| Single block | Mirror | program rotation | Axis exchange |

| Short back | Constant feed/ Servo feed | 2nd software limit | Axis Rotation |

| Auto aligment (edge, center) |

Dry run | Single block stop | Reference point setting |

| Reference point return | Retrace to start point/ Start point return |

Auto Power recovery (Option) | Diagnosis |

| Cutting log | Maintenance dashboard | Auto compensation for wire comsumption | Lead-in/ Lead-Out Control |

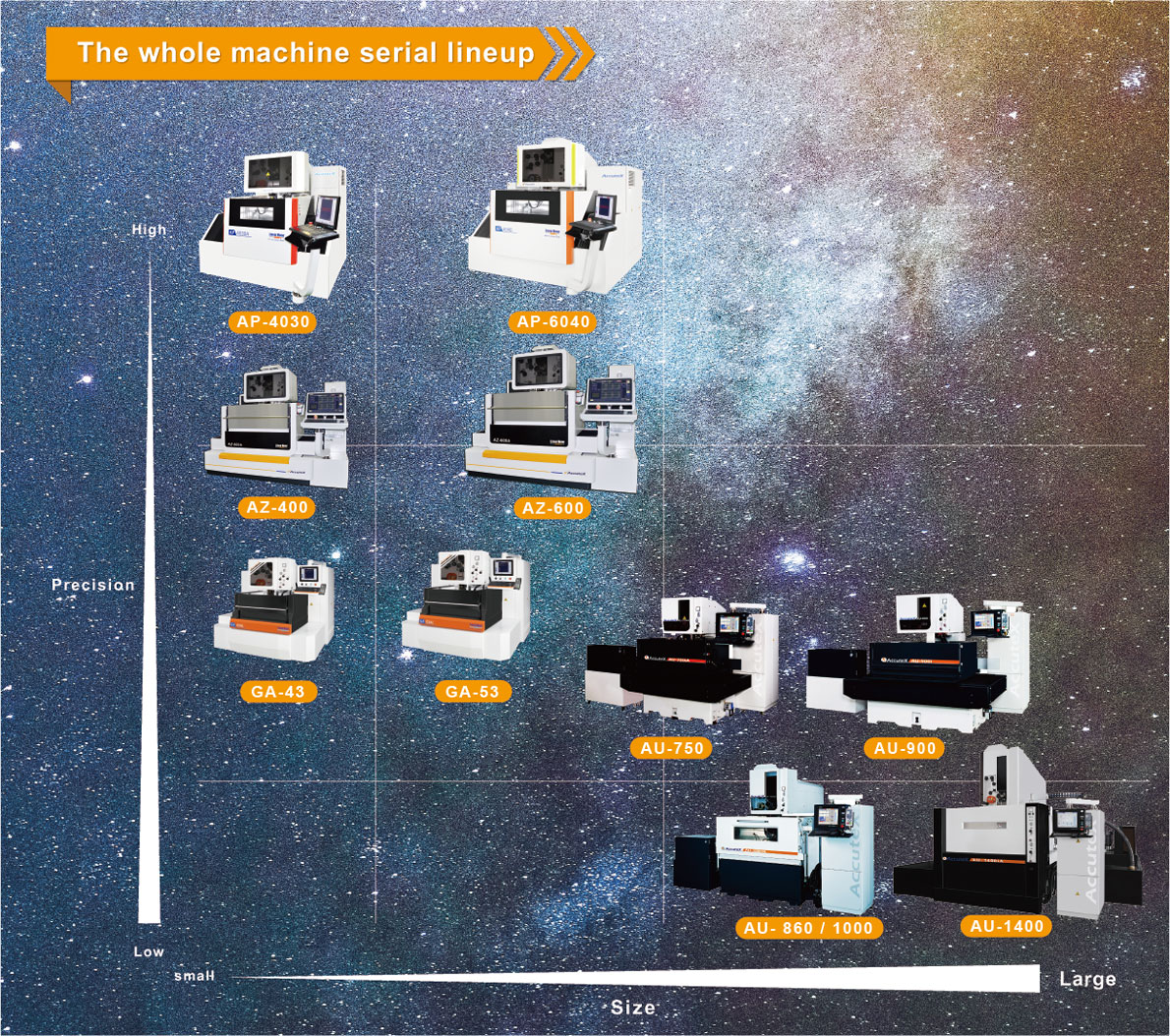

The whole machine serial lineup

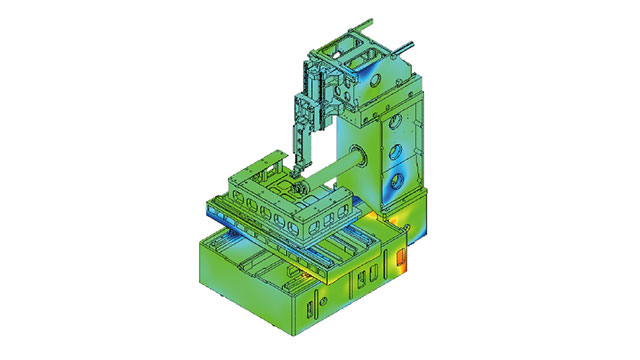

Machine Structure

AZ series has a "Direct Force" design on the concept of X/Y axes linear guideway blocks keep staying in a straight line.

The working table is supported by casting bases. AZ series is suitable for precision mold cutting within small/medium strokes.

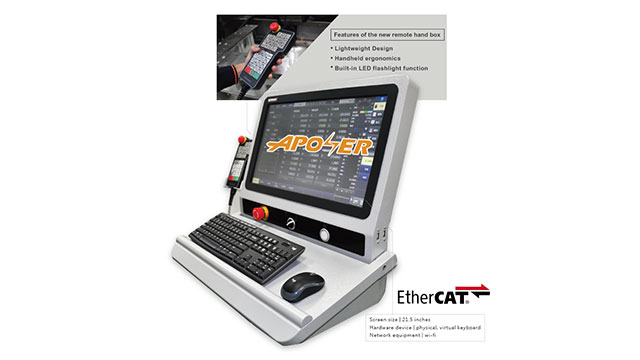

New Windows controller

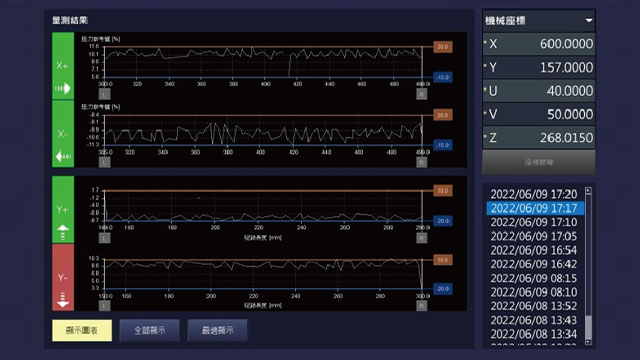

Motor Torque Monitoring System

100% automatic torque measurement of machine full stroke

Press one single key to kick off the auto-measurement of the full stroke torque, one single execution before cutting to realize the torque status of the full stroke operation. Ensures this is interference-free machining on the machine.

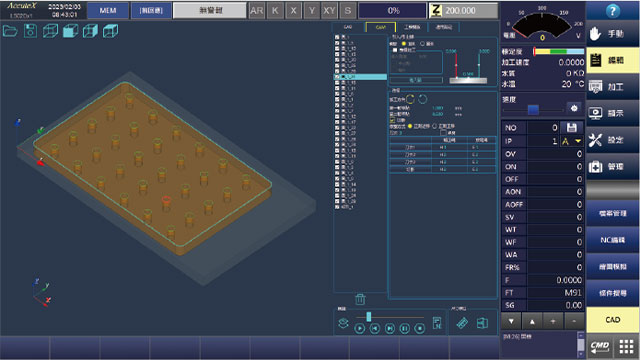

Built-in CAD/CAM

Process the complete POST-process before the cutting on the machine

The new controller has built-in the specified third-party post-processing software which supports loading the CAD drawing files. The NC program. can be generated on the machine after the standard post-process.

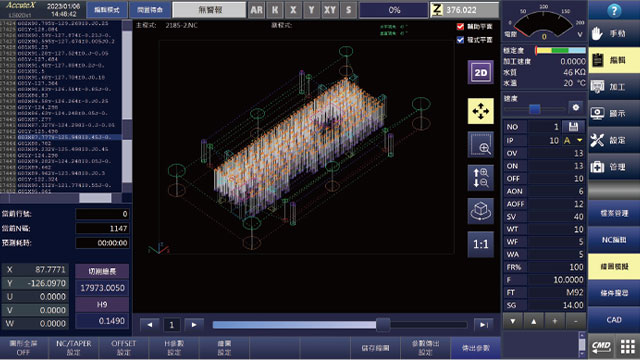

Fast drawing performance

Drawing speed increased by 300% and is able to have 3D full viewing

For large-scale programs, drawing smoothly and quickly, switch between 2D / 3D viewing, and viewing all detail position. In 3D mode, drag to change the viewing angle, and use the mouse wheel to zoom, clearly check the cutting path and improve the processing quality.

Automatic alignment

Faster, more accurate, one-click automatic processing

Press one button to complete the automatic plate width, outer circle, inner squarehole, four-sided center, and other calibration procedures. Different wire diameters can be matched with different wire tension and the wire speed settings. PICK-program is available to achieve full automation and unmanned operation. With the new edge-seeking function, the accuracy of the mold calibration is up to 3µm.

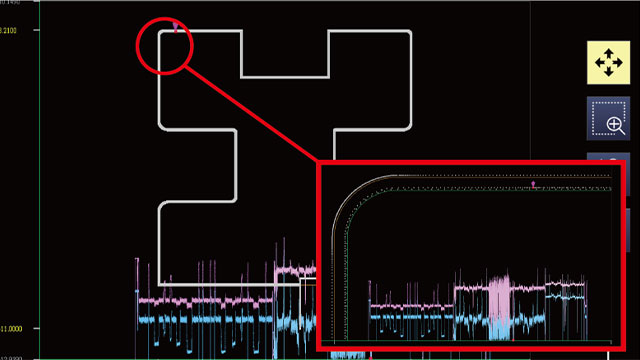

Processing history library

Processing History Search Record

The processing speed, discharge gap voltage, and other processing information are recorded by multi-tools in the whole path, and the user can quickly browse and check the processing process, Especially for the corner arc path and finishing process, the final machining result can be confirmed.

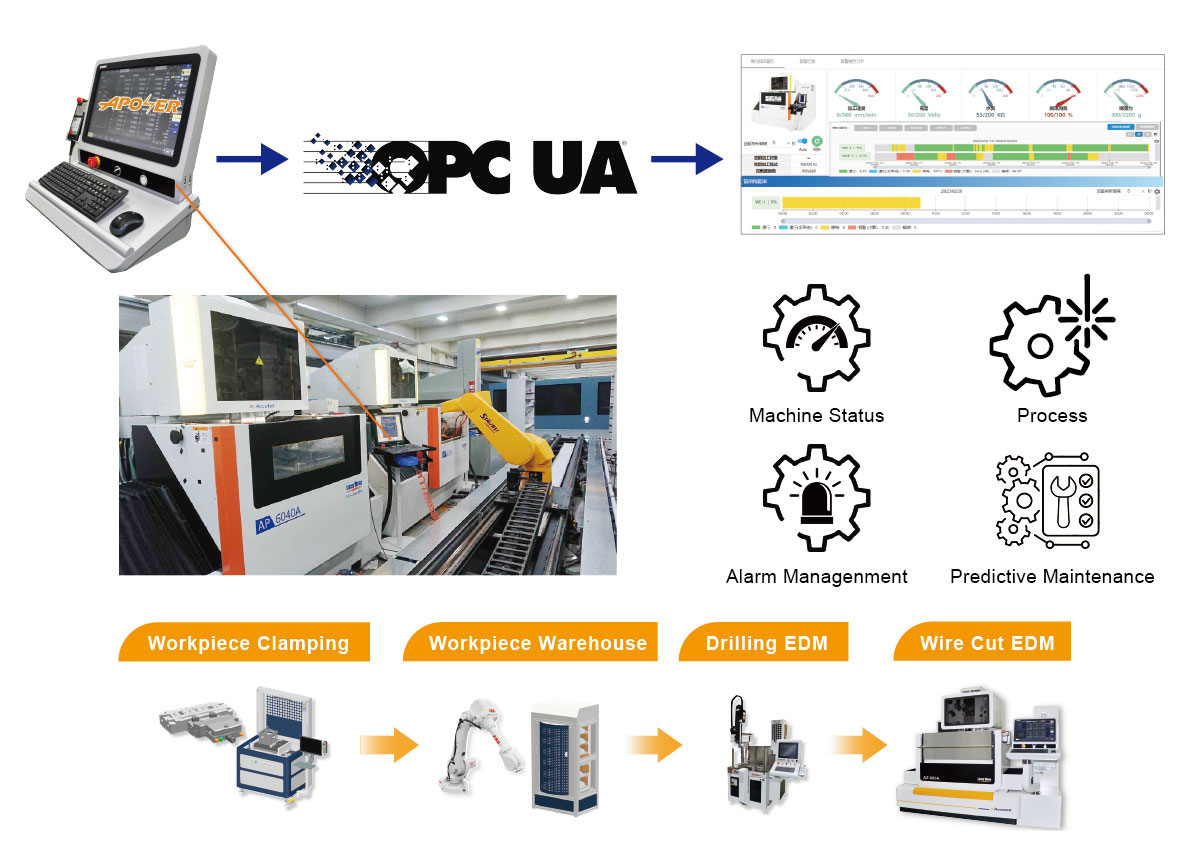

EtherCAT level control system

Dual industrial-grade PCs are equipped with high-performance CPUs and adopt Ethernet serial architecture to achieve high-speed and real-time

synchronous motion.The convenient EtherCAT universal expandability enables the machine to have more intelligent applications.

AccuteX machine is capable with industry 4.0 who has M2M (machine to machine) protocol to collaborate with Robots and other machines. Flexible Real-time production can be made by Intelligent Manufacturing Integration System to meet full-automation demand.

Download

Download