- Specifications

- Character

- Related Products

| Max. Work Piece Size L x W x H (mm) | 880 x 630 x 215 |

|---|---|

| Maximum height of cutting workpiece | 175 |

| Max. Work Piece Weight (kg) | 500 |

| X x Y stroke (mm) | 500 x 300 |

| U x V Stroke (mm) | 60 |

| Z Stroke (mm) | 220 |

| Max. Cutting Taper (mm) | ±15˚ / H80 |

| Max. Wire Spool Weigh (kg) | 10 |

| Foot Print W x D x H (mm) | 2200 x 2570 x 1995 |

| Water System Capacity (L) | 730 |

| Machine Weight (kg) | 3000 |

(*) “L” stands for linear motor optional function.

Controller Specifications

| Controller System | Windows |

|---|---|

| Control Device | 64 - bit Industrial PC |

| Storage Device | ≥ 30GB SSD |

| Screen Display | 21.5'' Color TFT Touch Screen |

| Data Input | Keyboard, Mouse, USB, Ethernet, FTP |

| Servo control method | Full closed loop (Linear scale) |

| No. of Control Axes | 5 Axes/ 6 Axes (Opt.W Axis) |

| Simultaneous Axes | 4 Axes/ 5 Axes (Opt.W Axis) |

| Min. Command Unit | 0.0001mm / 0.00001 inch |

| Max. Command Range | ±9999.9999mm |

| Command Type | mm / inch |

| Cutting data Memory | 99999 Sets |

| Power type | MOSFET Non-electrolysis power |

| Ignition Power Supply | 32 Steps,53V~138V |

| On time | 24 Steps |

| Off time | 43 Steps |

| Discharge Mode | Rough Cut/ Skim Cut/ S Power/ MST Power available for AP/AZ series only |

| Controller Functions | |||

|---|---|---|---|

| Backlash compensation | Pitch compensation | Program management | Program edit Program simulation |

| Anti- collision | Cutting path display | Linear/Circular interpolation | Auto corner |

| N code move | Sub program | Multi-blocks skip | Corner control function |

| MDI function | Taper setting | 4 axes cutting | M01 stop |

| Single block | Mirror | program rotation | Axis exchange |

| Short back | Constant feed/ Servo feed | 2nd software limit | Axis Rotation |

| Auto aligment (edge, center) |

Dry run | Single block stop | Reference point setting |

| Reference point return | Retrace to start point/ Start point return |

Auto Power recovery (Option) | Diagnosis |

| Cutting log | Maintenance dashboard | Auto compensation for wire comsumption | Lead-in/ Lead-Out Control |

Standard Accessories

- SD Master

- Manual Sliding door

- Upper/ Lower Flushing Nozzle

- Diamond Guide

- Conductor Plate

- Brass Wire

- Ion Exchange Resin

- Ion Resin Tank

- Paper Filter

- Waste Wire Bin

- Vertical Alignment Jig

- Diamond Guide Remove Jig

- Tools and Clampers

- Tool Box

Optional Accessories

- Transformer

- Auto Voltage Stabilizer

- Water Chiller

- PCD/ Graphite Power Module

- S Power Module

- Rotary Table Package (W axis)

- XY Axes Liner Motor

- 0.2μm Resolution Linear Scale

- Auto Wire Threading (AWT)

- High Pressure Water Jet Threading

- 45Kg Wire Jumbo Feeder

- Remote Master

- GSM Messenger

- Anti-Collision on Z-Axis

- Industry 4.0 Intelligent Manufacturing Integration System

- Safety Door Interlock

- Machine Status Indicator

- Touch Screen

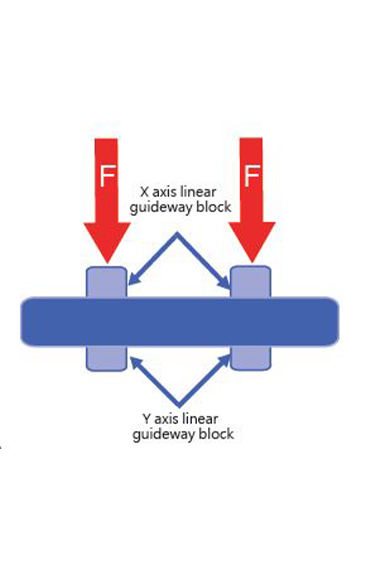

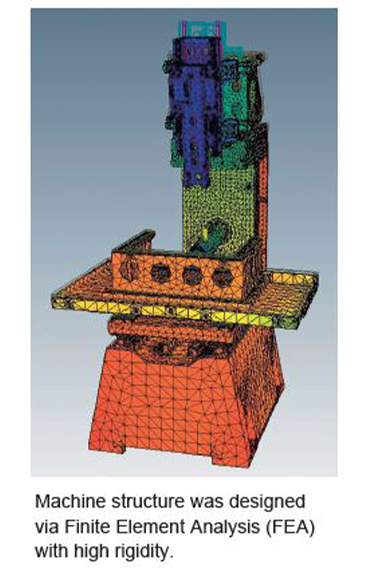

High-Rigidity Structure

GA series has "Direct Force" design on the concept of X/Y axes linear guideway

blocks keep staying in straight line.

Working table is supported by casting bases. GA series is suitable for the

precision mold cutting within small / medium stroke.

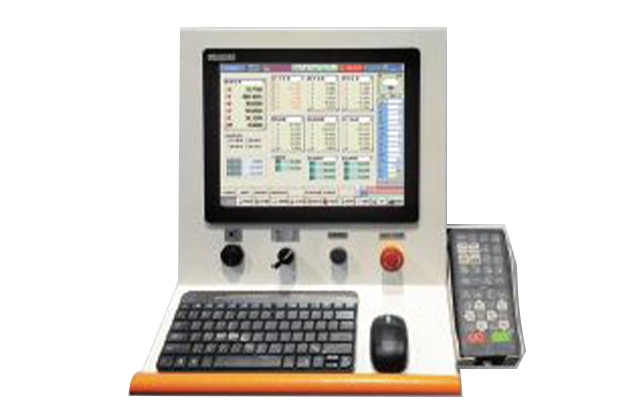

Windows CE Controller

AccuteX controller is 100% self-developed by core-technologies of R&D team. We can provide the best support in any modifications. AccuteX controller is based on Windows CE system. It features " Precise Motion Control " with rapid servo response.

Also, Windows CE system is virus free environment to assure system stability.

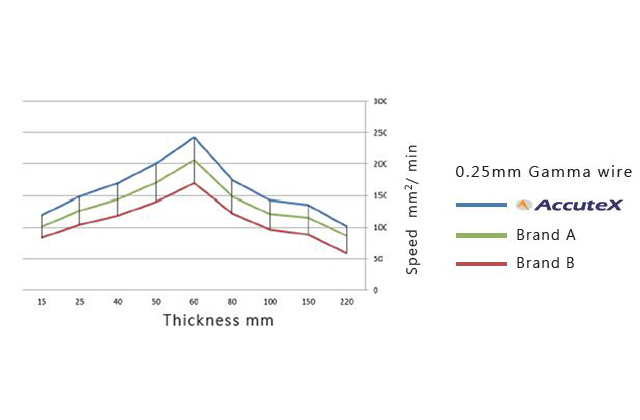

Cutting Efficiency Comparison

AccuteX has simplified the generator and electric circuits to eliminate unnecessary power loss and improve the cutting efficiency.

Speed comparison table with other brands in different thickness of workpieces.

Corner Control Function

According to different wire diameters, corner angles, arc radius and thicknesses, AccuteX controller optimizes parameters for the best cutting efficiency with high accuracy.

Especially on the small path and continuous corners, machines can meet the corner accuracy demand.

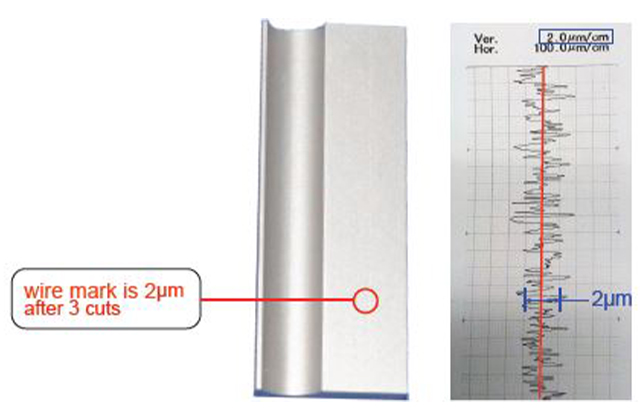

New Lead-In / Lead-Out Control

New generation of Lead-In / Lead-Out function is available for Tungsten Carbide.

The wire mark is 2μm after 3 cuts by 40mm thickness which improving mold quality and saving second time polishing hours.

Download

Download